How does film lamination work?

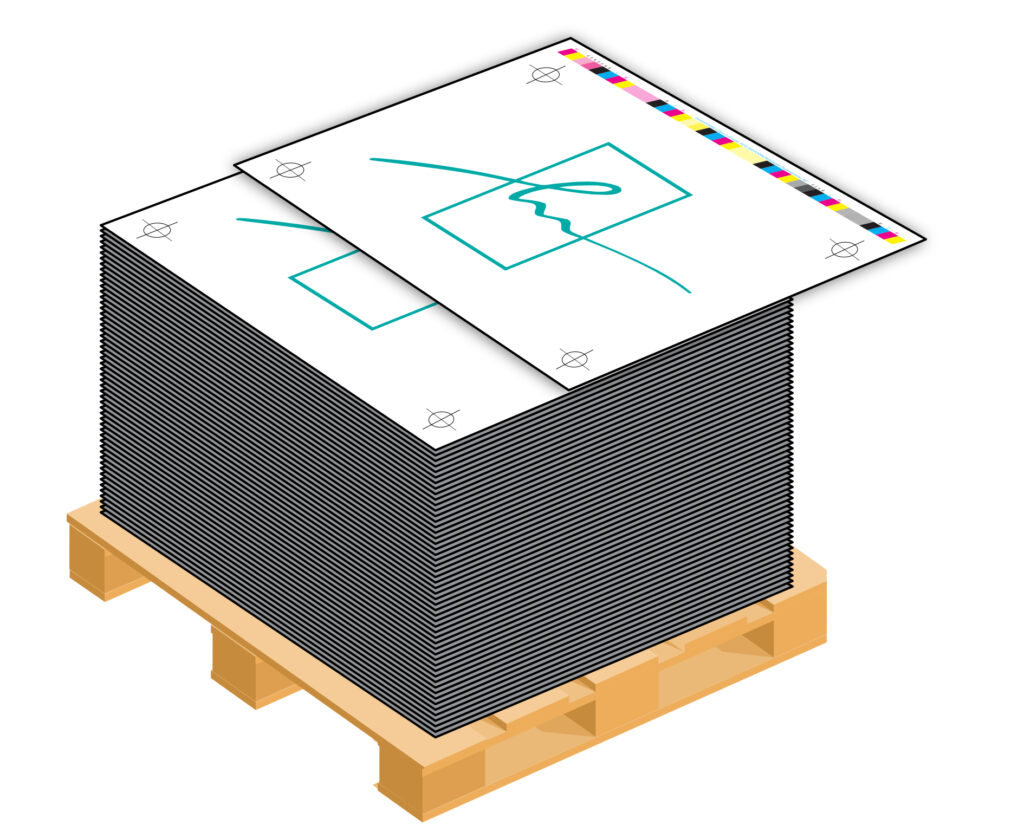

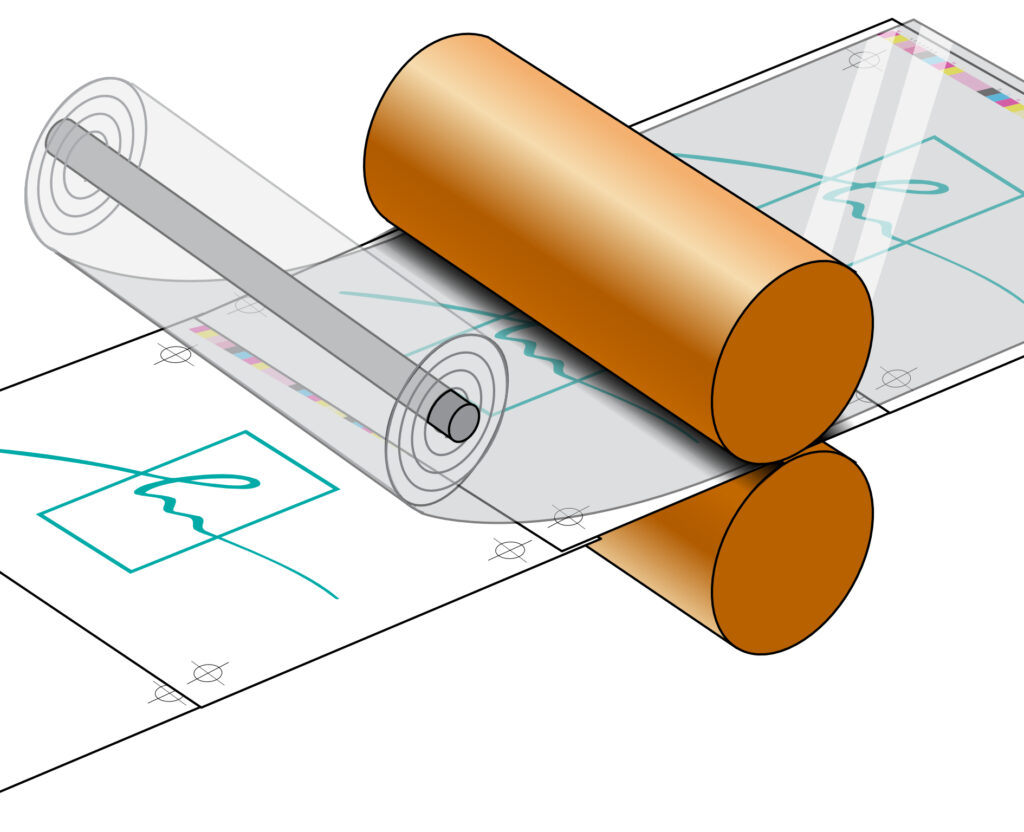

1.

The printed sheets are fed to the machine for finishing with film lamination.

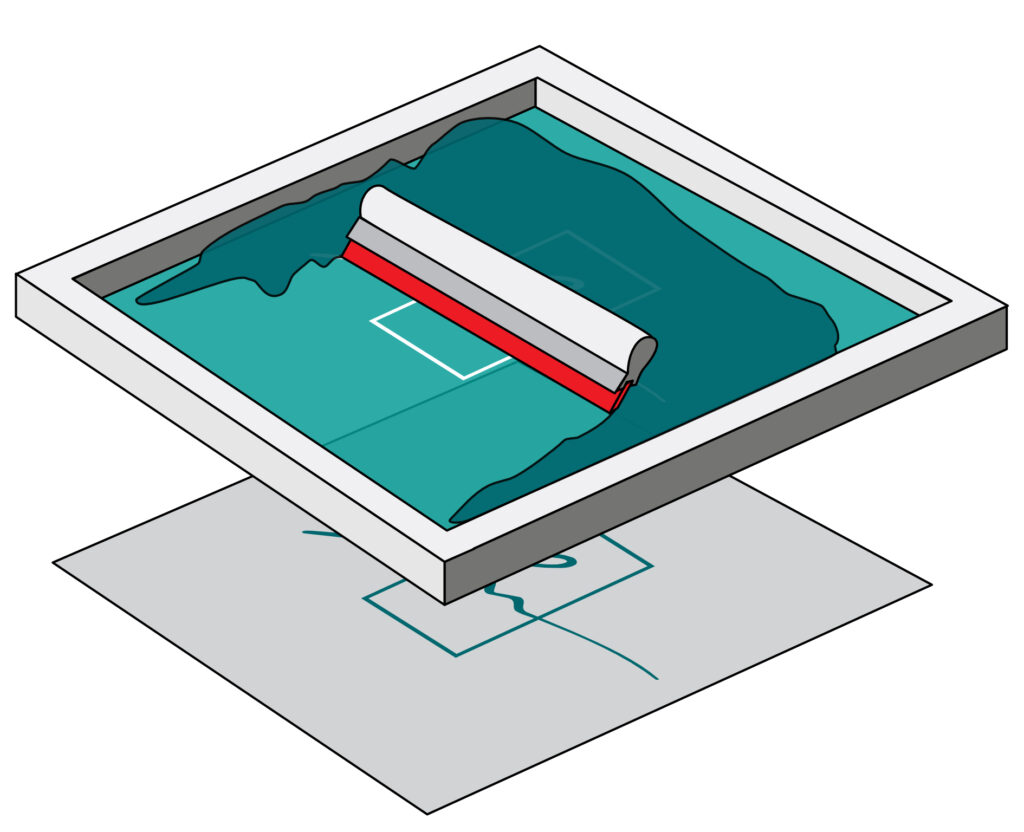

2.

The approx. 30 my thick film web is laminated cleanly and bubble-free using a roller mill.

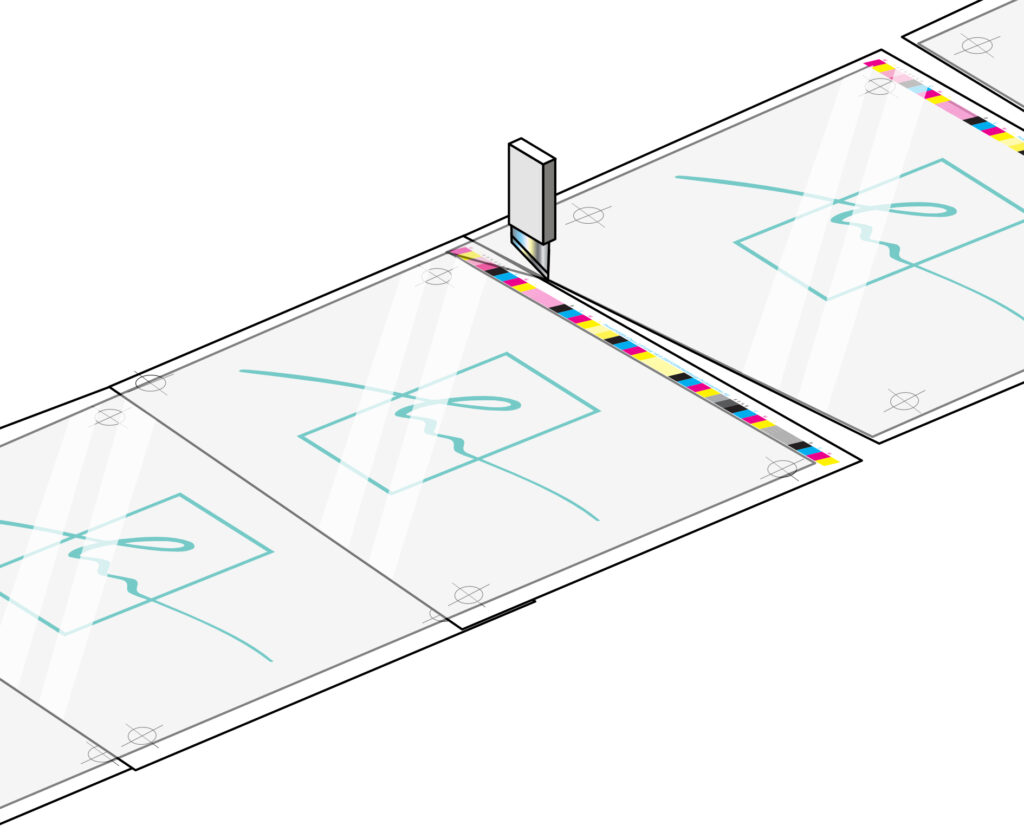

3.

The separating knife cuts the laminating film fully automatically and thus separates the sheets again.

4.

Advantages of film lamination:

Protection:

Protects against scratches, dirt and moisture.

UV protection reduces colour fading.

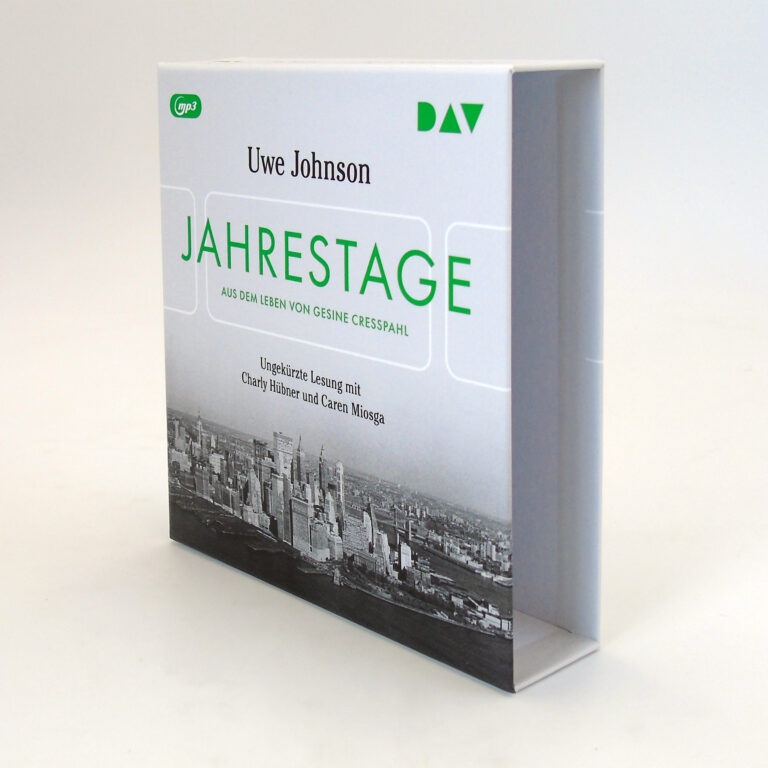

Optics/Haptics:

Gives a high-quality, elegant appearance.

Matt film lamination looks elegant and reduces reflections.

Glossy film lamination enhances the colours

Soft-touch film lamination for haptic effects and grip.

Functionality:

Makes cleaning and wiping the surface easier.

Increases resistance.

Extends the service life of the cardboard packaging.

Our house standards:

Film lamination

matt scratch-resistant

Film lamination

shiny

Film lamination

softtouch

For printed cardboard covers, we recommend film lamination for scratch protection.

Order sample box

Have a free sample box sent to you and see the quality of our packaging solutions for yourself. Shipping is free of charge.

Would you like advice on our products?

We will be happy to help you by phone or e-mail: